Various factors affecting solder quality

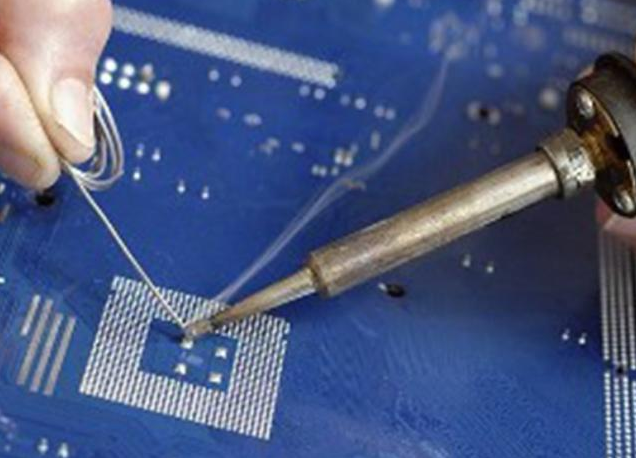

The proper amount of solder is critical to the quality of soldering, and improper amounts of solder can lead to a variety of problems.

If too much solder is used, it can lead to tin deposits on the solder joints, which can make the joints too heavy and may even form short circuits; on the other hand, if too little solder is used, it will not be enough to sufficiently wrap the joints, which may lead to the joints not being able to securely hold the components or the printed boards, and may easily be dislodged. Therefore, it is crucial to keep the amount of solder moderate.

Cold soldering refers to soldering problems caused by too low a soldering temperature, too short a heating time, or uneven soldering iron temperatures. In this type of soldering, the solder is not completely solidified, the surface is rough, there are cracks and other problems, which seriously affects the quality and mechanical strength of the solder joint. Therefore, increasing the soldering temperature, prolonging the heating time and ensuring that the soldering iron temperature is uniform are important measures to avoid cold soldering.

③ Clip rosin soldering is also a common soldering problem, it will lead to degradation of electrical connection performance. As a result of the solder and components or printed circuit boards between a layer of rosin, which will not only affect the mechanical strength of the solder joints, but also may lead to poor contact between the solder joints and the soldered components or printed circuit boards, and in serious cases, may even lead to a short circuit. In order to solve this problem, we should ensure that the proper amount of flux, while avoiding the use of rosin with too high a heating temperature during the soldering process, in order to prevent the formation of a black film affecting the quality of soldering.

④ Excessive flux will also lead to excessive rosin residue around the solder joint, which not only affects the appearance, but also reduces the mechanical strength of the solder joint. Therefore, the amount of flux used should be strictly controlled, and the rosin residue around the solder joint should be thoroughly cleaned up after the soldering is completed.

⑤ Solder bridging is a more serious soldering problem, which is usually caused by an excessive amount of solder resulting in a short circuit between the solder joints of a component. This situation requires special attention, especially when soldering ultra-small components and light printed circuit boards. In order to prevent the occurrence of solder bridging, the amount of solder should be strictly controlled, and ensure that the heating temperature and soldering iron angle during the soldering process is appropriate.

Engineers recommend that when hand soldering, special attention should be paid to the electrical connection properties, mechanical strength and surface smoothness of the solder joint. A good solder joint should have these characteristics to ensure that the components can work stably and reliably. In addition, the quality of soldering should be checked regularly to identify and solve problems in time to avoid potential pitfalls.

Tel:+86-13713635953

Tel:+86-13713635953 Email:luna@quicko.com.cn

Email:luna@quicko.com.cn